Anatomy of a Cabinet

A traditional cabinet is made up of the carcass which is the box that holds the entire storage unit together, with openings where external access is available for storage options. Storage options can be of several types:

· Doors

· Drawers

· Fixed Shelves

· Adjustable Shelves

· Partitions

· Pull Out Shelves

· Roll Out Drawer

· Accessories

These items are attached to the carcass by means of hinges, glides, pegs or screwed to the Carcass as complete assemblies.

Types of Cabinets

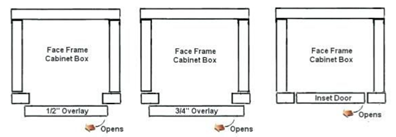

1. Face Frame Cabinet

a. A face frame cabinet has a finished wooden framework on the front to which the doors and drawer fronts are closed onto.

b. A Face-Frame cabinet gives much leniency to the overlap of the doors and drawer fronts to the face-frame cabinet and can often overlap well over 1 inch as there is no requirement to be exact.

2. Frameless Cabinet – Also known as European Cabinets or Euro-Cabinets

a. A cabinet without the front-facing frame has just the edges of the Carcass showing, which is edge-banded in the same color/finish as the doors and drawer fronts.

b. The doors and drawer fronts have to be exactly the size of the opening plus the “overlap” value which can be defined by the most popular values:

i. Full Overlay: This method covers mostly the entire thickness of the Carcass material, except for the “Reveal” portion which is usually 1/16 of an inch. When two doors, drawers, etc. meet, the distance between them will be twice the reveal value, in this case, 1/8 of an inch.

ii. Half Overlay: This method is used where a common part of the Carcass is getting an application of a door/drawer on both sides. In this case, the overlap is only half of the width of the carcass material, less the reveal allowance by the designer. Therefore if the carcass material is 3/4 inch and the reveal is 1/8 inch, then the “Half-Overlay” value will be half of the remainder of the width (which in this case will be 5/8”) so the half overlay will be 5/16 inch.

iii. Inset: This method shows the full width of the carcass material with the appropriate matching door/drawer edge banding, and the doors or drawers are flush with the outside edge of the carcass. This method is the most critical sizing and adjustment of the door or drawer, as an even, reveal of say 1/16 or 1/8 inch is on all four sides of the door or drawer.

Cabinet Materials

Cabinets’ carcasses are made from a variety of materials. Less expensive cabinets are often

n made from MDF (medium-density fiberboard) or particleboard that’s covered with melamine, thermofoil, or wood veneer. Over time, cabinets made from particleboard generally don’t hold up well to wear and tear. Better quality cabinets are made from plywood because it’s strong and its smooth veneer makes a great substrate for either paint or a clear finish such as lacquer. Less common and pricier are sleek cabinets (often imported) made from enameled steel or aluminum.

Doors and drawer fronts follow a similar line of quality: less expensive faces are made from MDF that’s painted or has some sort of veneer applied. More expensive and durable are frame and panel doors, whose frames are made of solid wood. Their panels, flat or raised, can be made from plywood, MDF, or solid wood.

Cabinet Finishes

The Ideal cabinet finish is one that is tough enough to resist scratches and scuffs and is easy to clean, year after year. Melamine and thermofoil excel in these characteristics—they are a form of plastic, after all—but their color choices are limited, and they’re often paired with lower-quality substrates.

The most widely used finish among professionals is some form of a sprayed two-part lacquer. It can be tinted to any shade and opacity and dries to an extremely durable, smooth finish. When buying custom cabinets, some homeowners may also opt for a hand-applied finish such as tung oil that accentuates the highlights of the wood grain.

These softer finishes don’t protect as well as lacquer and must be re-applied periodically.

Buyers’ Guide to Cabinet Types

When buying cabinets, there are three basic levels from which to choose: stock, semi-custom, and custom.

Here, cost relates to the options made available to the buyer. Cabinet pricing is generally expressed in terms of linear feet and can vary widely within the levels of quality. Stock cabinets are readily available and the least expensive, but are somewhat limited in configurations, styles, and finishes. The overall quality is often barebones. Semi-custom cabinets are typically more expensive than stock but are offered in a much wider array of styles and finishes and manufactured with better-quality materials. Expect a wait of up to several weeks for delivery.

Custom cabinetry is the most expensive, but the tradeoff is that you get exactly what you want. Often made in a local shop, the quality of materials and craftsmanship is top-notch. Delivery wait times can be longer than those of semi-custom cabinets.

Installing New Cabinets

New cabinet installations have the potential for some homeowner involvement. Installing a single cabinet can be a relatively straightforward task, well within the abilities of even the greenest DIY’er. The job requires a few basic tools (cordless drill/screwdriver, Phillips screwdriver, measuring tape, flat bar), shims, and a carpenter’s level. Identify where the framing lies inside the wall, make sure the cabinet is level and plumb, and screw it to the studs.

The process gets trickier as the number of cabinets increases – you must take into account the levelness of the floor, the straightness (or lack thereof) in the walls, jogs in the cabinet layout, angles, elevation changes, spaces for appliances, etc. At some point, it may be a good idea to call in the pros.

Professional installers have the experience and tools to transform a jumble of boxes into an assembly of clean lines, crisp reveals, and most importantly, great storage.

Cabinet Care

Over their lifetime, cabinets will get a lot of use, so a little routine maintenance will keep them looking great and working properly. When cleaning the cabinet surfaces, be aware of their finishes and don’t use harsh chemicals or abrasives. Cabinet hardware such as hinges and drawer slides may need periodic adjustments to keep doors and drawers aligned and working. Doors that don’t close properly can become warped over time. Most modern hinges and slides can be adjusted with a Phillips screwdriver in a couple of minutes.

Repairing and Restoring Cabinets

Over time, less expensive cabinets, especially those made of particle board, may deteriorate to the point where shelves are bowed, doors are warped, and the material just won’t hold screws anymore. Replacement is the only answer. But if the cabinets are just worn or dowdy, a homeowner may choose to give the existing cabinets a facelift instead. Chipped or worn areas can be touched up with paint or finish. Small areas of peeling veneer can be reattached by squeezing carpenters glue in between the laminations and clamping them with painter’s tape.

Changing the doorknobs and drawer pulls is another upgrade that won’t break the bank. There are literally thousands of styles from which to choose, and sometimes a new set of sleek drawer pulls in brushed chrome is just what your cabinets needed.

If the structure of the cabinets is still sound, a new coat of paint will go a long way to making a kitchen or bath shine again. Interior latex house paint offers the broadest options for color, is easy to use, and is the key ingredient in lots of money-saving kitchen remodels. However, for a quality paint job, even the simplest cabinet styles require a sizable investment in time. All surfaces to be painted should be cleaned, sanded, and dusted before the paint can be applied. Painting kitchen cabinets can also be left to professional painters. This is especially advisable if the cabinets in need are clear finished, in which case a painting contractor may choose to spray them in place.

As an alternative to paint, some homeowners opt to reface cabinets. Suitable for DIY’ers or a professional crew, refacing is the process in which adhesive-backed veneer is applied to the cabinets’ surfaces. Typically, new doors and drawer fronts are installed at the same time. While refacing is a less expensive option than replacing the cabinets, as with painting, it only makes sense if the cabinets are in good structural shape.

Comments